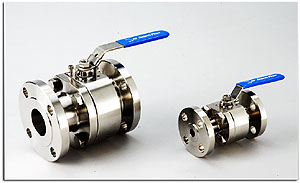

Standard and Custom Designed

Products

Our range of standard valves is wide. In addition, we can supply custom-designed

products to meet your needs. Tell us about your particular requirements and we

will respond quickly with concepts that deliver cost-effective results.

Rigid Program for On-time

Delivery

Meeting customers' delivery requirements has been

a top priority. Our production schedule has

been programmed to meet this goal with consistent reliability. We have

implemented "Quick Delivery" program to ship "In-Stock" orders within 2 weeks

for urgent shipments.

Strict Quality Assurance to

Ensure Better Products

We have the modern facilities and the dedicated people to turn your concept of

quality into a investment casting. Every process is strictly controlled since we

produce investment castings for demanding applications, repeatability of

dimensions is critical quality must be maintained at the highest level. Both wax and metal samples are dimensionally checked and recorded at the layout stage. In-process inspections are implemented at various production checkpoints to ensure uniform results.

Quality Control - ISO 9001 Certified

Sets forth written systems and procedures to maintain quality assurance throughout the manufacturing process, in accordance with ISO 9001 requirements. Specific customer requirements

can be incorporated to assure customer expectations are consistently met or exceeded.

|