Latest News

-

AF-36C

&

AF-51C

Cryogenic

Ball Valves passed BS 6364 Cryogenic Test AF-36C

&

AF-51C

Cryogenic

Ball Valves passed BS 6364 Cryogenic Test

-

This testing requires immersion in

liquid nitrogen @-321F for one hour, then (20) cycles at full rated

pressure (2000 psig) with helium as a test gas, then valve is tested

for both external & across-valve leakage with helium...

AF-60

Sanitary

& High

Purity Ball Valves

for gas or processing cooling water in

Semiconductor, pharmaceutical or food Industry. AF-60

Sanitary

& High

Purity Ball Valves

for gas or processing cooling water in

Semiconductor, pharmaceutical or food Industry.

Spring

Return Handle

Ball Valves

Spring Return Closes valves when not held open providing

safety for applications that requires positive closure. Locking

device lock the valve in preferred position. Spring

Return Handle

Ball Valves

Spring Return Closes valves when not held open providing

safety for applications that requires positive closure. Locking

device lock the valve in preferred position.

AF-51F

150 ~ 300#

Flanged

Direct Mount

Ball Valves

Firesafe certified to API

607 7th Edition. AF-51F

150 ~ 300#

Flanged

Direct Mount

Ball Valves

Firesafe certified to API

607 7th Edition.

AF-35

2000 PSI

3-pc

Direct Mount

Ball Valves

Firesafe

certified

to API 607 7th Edition. AF-35

2000 PSI

3-pc

Direct Mount

Ball Valves

Firesafe

certified

to API 607 7th Edition.

AF-291

6,000 PSI

High Pressure Ball Valve

Seal Welded,

ISO 5211 mounting,

Delrin Seat.

Locking Handle or Bare Stem for

Actuation.

Option:

Firesafe to API 607

5th Edition. AF-291

6,000 PSI

High Pressure Ball Valve

Seal Welded,

ISO 5211 mounting,

Delrin Seat.

Locking Handle or Bare Stem for

Actuation.

Option:

Firesafe to API 607

5th Edition.

Contact

Anson

for

details.

adDress

Anson Flow Corp.

7F-2, No. 408, Nantun

Rd., Sec.2, Taichung City 408 438, Taiwan

Phone: +886 4

2472 0998

Fax:

+886

4

2473 4240

E-Mail:

sales@ansonflow.com

|

Quality

Investment Castings

for a wide variety of OEM markets

|

|

Investment

casting has, with no doubt, earned it's place in manufacturing. The

lost-wax process has proven to be a cost effective way to produce metal

components. Parts can be reduced in weight, tolerances of 0.010" or

0.13mm per inch held, The average micro finish is 125 rms, with the

range for the process being between 60 and 120, depending upon the

limitations of the metal, and expenses and time involving machining and

finishing reduced or eliminated.

Our commitment is

to produce high quality castings. It takes a well planned facility, the

right equipment, and well trained people dedicated to quality to achieve

consistent results. It can be always told in our final product. The

lost-wax process provides unique opportunities for engineers and

designers. Intricate structures can be created with minimum or no

secondary machining operations.

|

Quantities:

|

50 pcs to 10,000 pcs |

|

|

-

Prototype delivery as little as 3 weeks

|

|

Metals: |

Poured: iron, nickel and cobalt base

alloys: |

|

|

-

Carbon & Low Alloy Steels

-

400 Series Stainless Steel

-

300 Series Stainless Steel

-

Precipitation hardening Stainless Steel

-

Tool Steels

-

Cobalt Base Alloys

-

Nickel Base Alloys Alloy Cast Iron

|

|

Weight:

|

Up to 45 kgs. depending upon part configuration |

|

Size:

|

Up to 18" x 18" x 18", to 24" length in some cases. |

|

Process:

|

Lost-Wax process, shell method |

|

Capability:

|

We employ the latest production

and testing technology to assure high quality at a competitive price.

Customers can find every necessary special service: pattern-making, heat

treating, machining, CAD/CAM, rapid prototyping, physical and chemical

analysis, magnetic particle penetrant inspection, x-ray, dye checking,

microstructure evaluation, mechanical and non-destructive testing, alloy

control, lab services, microscopic analysis testing, design and layout

services. |

|

Applications: |

- Compressors

- Valves

- Pumps & Impellers

- Propellers

- Automotive

- Food Processing

- Hand Tools

- Machine Parts

- Hardware

- Golf Clubs

- Marine Hardware

- Marine Parts

- Medical

- Packaging

- Pneumatic Tools

|

Investment Casting Process

|

|

Wax which conforms to complex cavities and intricate exteriors is

injected into precisely tooled dies which, while accounting for both wax

expansion and metal contraction, yield finished tolerances of ?.0057.

|

|

The resulting wax patterns are assembled on a tree, or sprue, which

provides the gates through which the molten metal will be poured.

|

|

|

|

|

The tree is dipped repeatedly into ceramic investment, strong enough to

handle molten metal but pourous enough to allow air to escape, thus

preventing voids. |

|

After the wax is burned out of the ceramic mold, hence the term "lost

wax," molten metal is poured into the resulting pattern at up to

3,000°F. |

|

|

|

|

The heat of the casting alters the ceramic chemistry so the mold

crumbles away after cooling. Gates are then cut off and the part is

cleaned. |

|

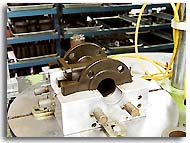

Finished parts are checked

for allowable tolerances. Non-destructive testing, X-ray, magnetic particle and penetrating dye

inspections are available. |

|

|

|

|

|

Final Quality Inspection:

Specialized technician examines dimensions, hardness and microstructure

by hardness test, tensile test, & impact test to ensure quality

conformance to specification. Material Certificate & Inspection Report

is issued accordingly. |

|

|

|