|

|

Flanged

Valve / ANSI

AF-50T

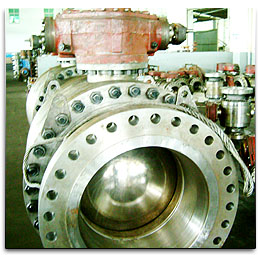

Trunnion Mounted/ Full Bore

|

|

Design

Std. |

API 6D, ASME B16.34 |

| Face to

Face |

ASME B16.10 |

| Testing

Std. |

API 6D, API 598 |

| Size Range |

4" -

36" |

| Pressure Rating |

Class 150 -

2500 |

| Seat Material |

PTFE / NYLON |

View

Dimensions View

Dimensions

|

Send Inquiry Send Inquiry

|

|

|

Design

Features:

-

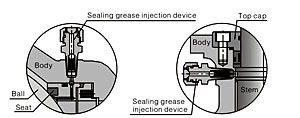

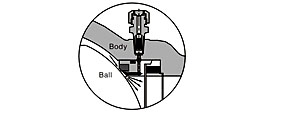

Urgent Grease Injection Device

According to customers

requirement, the trunnion ball valve ca be provided with

devices for urgent grease injection, which are on both the

stem and seat for trunnion ball valves of DN>150mm(NPS6), and

in the body cavity for the valve of DN<125mm. When the O ring

of stem or the body seat ring is damaged due to accident,

leakage between body and stem can be prevented by injecting

the sealing grease through the device.

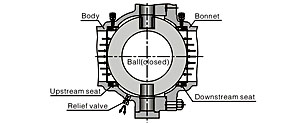

In general, our trunnion ball

valve features the front ball sealing design structure. Each

seat of the ball valve can separately cut off the medium at

both inlet and outlet of the valve to realize double-block

functions. When the ball valve is closed, body cavity and two

of the body ends can be blocked with each other even if both

the inlet and outlet are under pressure, when the medium left

in the body cavity might be bled through the relief valve.

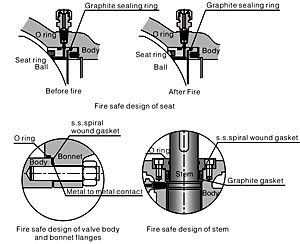

In the event of fire, the

non-metal parts such as seat sealing ring of PTFE, O ring for

stem and sealing gasket for body and bonnet, might be damaged

due to high temperature. Our special design of auxiliary metal

to metal or the graphite seal is provided in the trunnion ball

valve to effectively prevent both internal and external

leakage of the valve. As required by customers, our fire safe

design for the trunnion ball valve meets the requirement API

607, API 6Fa, BS6755.

As the liquid medium left in

the body cavity gasifies due to increased temperature, the

pressure in the body cavity becomes abnormally higher, when

the medium itself in the cavity would propel the seat and

self-relieves the pressure o ensure the safety of valve.

-

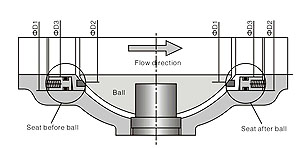

Bi-sealing Design -

seat sealing in front of ball and

behind ball

According some special

working conditions and customers requirement, we can

provide trunnion ball valve with the Bi-sealing design

structure, i.e. seat sealing in front of the ball and seat

sealing behind the ball, so the reliable sealing of the

valve is ensured, the valve can work normally even if one of

the effective sealing designs becomes lost due to abnormal

condition. Regarding the seat in front of the ball, the piston

effect formed by the area difference between D1 and D2, plus

the pre-tightened force of a spring would cause the seat in

front of the ball by the pressure difference of the medium

before and after the valve to touch the ball closely to form

the tightness, of which the sealing force will become bigger

as the pressure difference gets higher.

-

Blow-out Proof Stem

-

Anti-static Device

Applicable

Standards & Specifications:

- Design and Manufacture : API 6D, API

608, ASME B16.34, MS SP-72, BS 5351, BS6364,

ANSI/AWWA C507, BFCI 70-2, ISO 5211

- Connection Ends : ASME B16.5, B 16.47,

API 605, MSS SP-44,

ISO 7005-1, JIS B2238, BS 12627, ASME B16.25, ASME B16.11,

BS 12760

- Face to Face Dimension : ASME B16.10,

ISO 5752, BS558, BS12982

- Inspection & Testing : API 6D, API 598,

API 607/API 6FA, BS6755, BS 12569,

MSS SP-61

- Nominal Pressure Rating : Class 150 -

2500, JIS 10K - 20K, PN10 - 160

- Nominal Diameter or Bore : NPS 4 - 36, DN50 -

900

- Applicable Temperature: -196 °C to 540

°C

- Manual, Worm Gear, Pneumatic, or

Electrical Operations

|

|

|